What Is 2RSB9053?

The 2RSB9053 is a high-performance bearing widely recognized for its exceptional reliability, strength, and smooth operation in demanding engineering systems. While the name might appear as just another alphanumeric code, it represents a precision-engineered component designed to ensure frictionless motion between rotating parts. In modern mechanical systems—whether in aerospace, automotive, or industrial automation—such bearings play a crucial role in maintaining performance and longevity.

Engineers and technicians across various industries depend on this specific bearing model to deliver consistent results under challenging conditions. The component has earned its reputation through years of proven performance in applications where failure is not an option. From high-speed machinery to heavy-load equipment, the 2RSB9053 continues to set standards for what a professional-grade bearing should deliver.

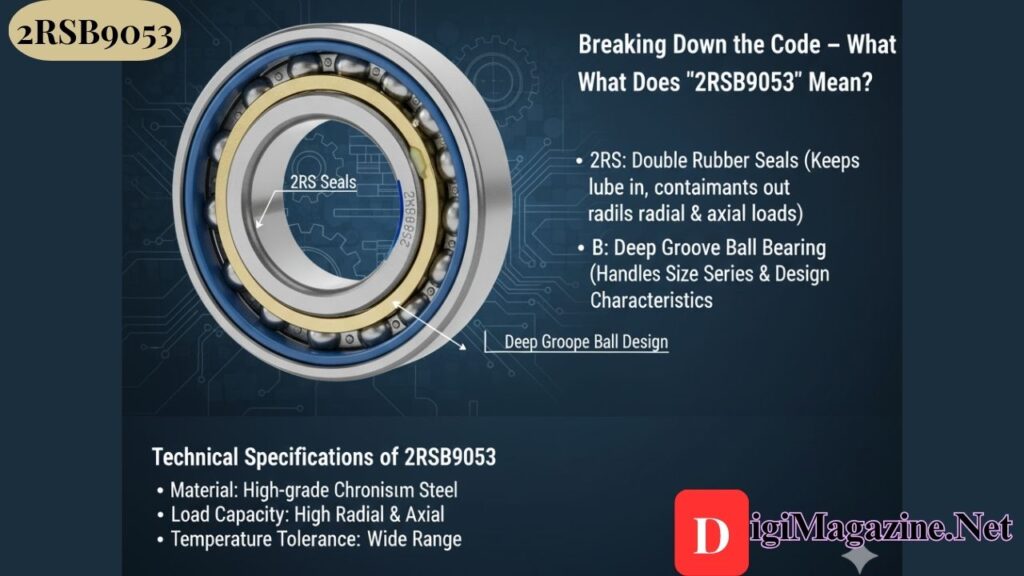

Breaking Down the Code – What Does “2RSB9053” Mean?

Understanding the nomenclature behind bearing designations helps professionals select the right component for their specific needs. The code 2RSB9053 contains valuable information about the bearing’s design and protective features.

The “2RS” prefix indicates a double rubber seal configuration, which means the bearing comes equipped with protective seals on both sides. These seals serve a critical function by keeping lubricants inside while preventing contaminants like dust, dirt, and moisture from entering the bearing assembly. This dual-seal design significantly extends the operational life of the component.

The “B” in the designation typically refers to the deep groove ball bearing category. Deep groove designs are favored for their ability to handle both radial and axial loads while maintaining smooth rotation. The numerical portion “9053” represents the specific size series and design characteristics that distinguish this model from other bearings in the same family.

Technical Specifications of 2RSB9053

Precision engineering demands exact specifications, and the 2RSB9053 delivers on multiple technical fronts. The bearing features dimensions carefully calibrated to meet industry standards while providing optimal performance across diverse applications.

The core construction utilizes high-grade chromium steel or specialized alloys chosen for their superior strength-to-weight ratio. This material selection ensures the bearing can withstand substantial forces without deformation or premature wear. The hardened steel balls inside the assembly are manufactured to tight tolerances, ensuring consistent rolling action and minimal friction.

Load capacity represents another crucial specification. The 2RSB9053 handles both radial loads—forces perpendicular to the shaft—and thrust loads that push along the shaft’s axis. This dual capability makes the bearing versatile enough for complex mechanical systems where forces come from multiple directions.

Temperature tolerance is equally impressive. The bearing maintains its performance characteristics across a wide thermal range, from cold environments to elevated operating temperatures. The seal material, whether nitrile or fluoroelastomer rubber, is selected based on the expected operating conditions and chemical exposure.

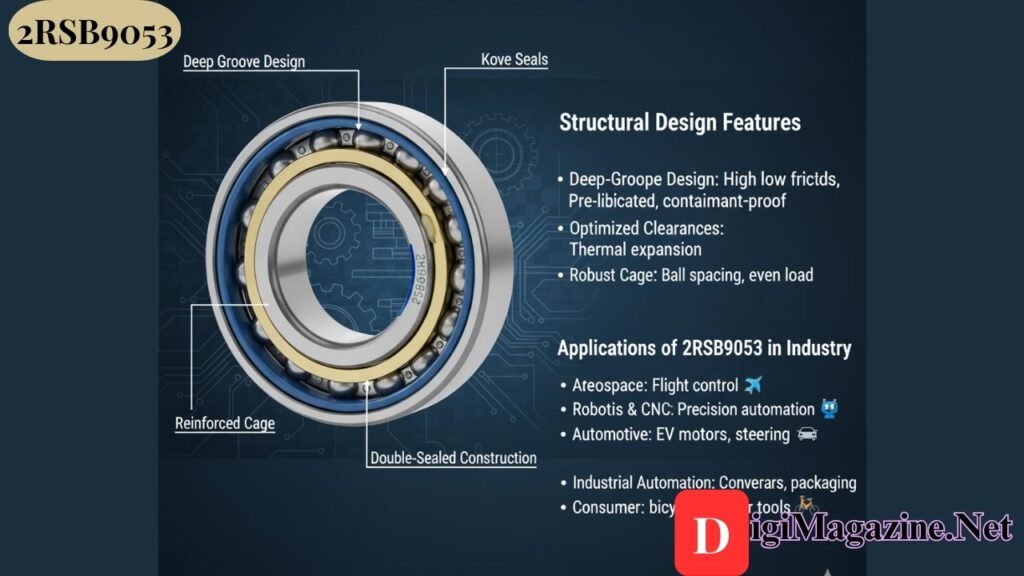

Structural Design Features

The deep-groove design stands out as one of the 2RSB9053’s most significant structural advantages. This configuration allows the bearing to accommodate higher loads while maintaining exceptionally low friction levels. The grooves are precisely machined into the inner and outer races, creating optimal contact paths for the rolling elements.

Double-sealed construction provides comprehensive protection against environmental factors. Unlike open bearings that require constant attention, the sealed design means the 2RSB9053 arrives pre-lubricated and ready for installation. The seals themselves are engineered to maintain contact pressure that prevents ingress without creating excessive drag.

Internal clearances are optimized to allow for thermal expansion during operation. As machinery heats up during use, components naturally expand. The bearing’s internal design accounts for this expansion, preventing binding while maintaining proper load distribution across all rolling elements.

The cage or retainer design ensures proper spacing between the balls throughout operation. This component, often made from steel or high-strength polymer, prevents the rolling elements from contacting each other directly. Proper spacing reduces friction and heat generation while distributing loads evenly.

Applications of 2RSB9053 in Industry

Aerospace engineering relies heavily on components like the 2RSB9053 for critical flight control systems. The bearing finds use in actuators that adjust control surfaces, stabilizer mechanisms that maintain aircraft balance, and various servo systems that respond to pilot inputs. In this sector, reliability isn’t just important—it’s mandatory for safety.

Robotics and automated manufacturing systems benefit from the bearing’s precision and durability. Robotic arms that perform repetitive tasks thousands of times daily need bearings that won’t fail unexpectedly. CNC machinery that cuts and shapes materials with micron-level accuracy depends on smooth, predictable motion that the 2RSB9053 consistently provides.

The automotive industry incorporates these bearings in multiple subsystems. Electric motor assemblies, steering mechanisms, and transmission components all require bearings that can handle varying speeds and loads. The sealed design proves particularly valuable in automotive applications where exposure to road debris, water, and temperature fluctuations is inevitable.

Industrial automation equipment uses the 2RSB9053 in conveyor systems, packaging machinery, and assembly line robotics. These applications often involve continuous operation over extended periods, making the bearing’s durability and low-maintenance characteristics extremely valuable.

Beyond heavy industry, the bearing also serves consumer applications. Bicycles benefit from the smooth rolling action and weather resistance. Skateboards equipped with quality bearings deliver better performance and longer service life. Even home appliances like washing machines and power tools may incorporate similar bearing technology for quieter, more reliable operation.

Performance Benefits of the 2RSB9053 Bearing

Minimal friction translates directly into energy efficiency and reduced heat generation. When mechanical systems operate with lower friction levels, they consume less power and experience less wear. This efficiency becomes particularly important in battery-powered devices or systems where energy costs represent a significant operational expense.

Noise reduction is another tangible benefit. Properly manufactured bearings with tight tolerances operate quietly, which matters in both consumer products and professional environments. Excessive bearing noise often signals improper installation or component degradation, but the 2RSB9053’s precision manufacturing ensures quiet operation when correctly installed.

An extended lifespan reduces the total cost of ownership. While the initial purchase price matters, the true value emerges when considering maintenance intervals and replacement frequency. The double-sealed design protects internal components from contamination that causes accelerated wear, allowing the bearing to maintain performance standards over longer periods.

Versatility across operating conditions expands the range of possible applications. The bearing performs reliably whether rotating at high speeds or under heavy loads. This adaptability means engineers can specify the same component across different projects, simplifying inventory management and reducing procurement complexity.

Resistance to environmental factors protects the bearing in challenging conditions. Moisture resistance prevents corrosion that would otherwise degrade performance. Heat resistance ensures the bearing maintains its properties even when surrounding components reach elevated temperatures during demanding operations.

Installation Best Practices

Proper installation begins with thorough preparation. The mounting surfaces must be clean, smooth, and free from burrs or debris that could cause misalignment. Any contamination introduced during installation can compromise the sealed environment that protects internal components.

Press-fitting requires appropriate tools and techniques. The force should be applied evenly to the bearing race that will be interference-fitted—typically the inner race when mounting on a shaft. Applying force through the rolling elements risks creating indentations in the races, which leads to noise and premature failure.

Alignment is critical for optimal performance. Even slight misalignment creates uneven load distribution, accelerating wear on specific areas of the bearing. Using precision measuring tools ensures the bearing sits square to the shaft and housing, maintaining proper geometry throughout operation.

Temperature considerations affect installation methods. Some professionals use thermal techniques, either heating the housing or cooling the bearing, to ease installation. These methods reduce the force required and minimize the risk of damage, but they must be executed carefully to avoid overheating seals or creating excessive clearances.

Post-installation verification confirms proper setup. Rotating the shaft by hand should feel smooth and consistent without binding or rough spots. Excessive resistance might indicate misalignment, contamination, or damage that occurred during installation.

Maintenance Tips for Extended Lifespan

The sealed design simplifies maintenance significantly. Unlike open bearings that require regular lubrication intervals, the 2RSB9053 arrives pre-lubricated with enough grease to last its entire service life under normal conditions. This sealed-for-life design eliminates maintenance tasks related to regreasing.

Regular inspection remains important even for sealed bearings. Visual checks can identify external damage, seal integrity issues, or mounting problems before they lead to failure. Looking for lubricant leakage around seals provides early warning of potential problems.

Vibration monitoring offers insights into bearing condition. Accelerometers attached to machinery housing can detect frequency patterns associated with bearing wear. Increases in vibration levels or changes in frequency spectrum often precede outright failure, allowing for planned replacement rather than emergency repairs.

Temperature monitoring complements vibration analysis. Infrared thermometers or thermal imaging cameras can identify bearings running hotter than expected, which might indicate lubrication breakdown, excessive loading, or alignment issues. Addressing temperature anomalies early prevents catastrophic failures.

Operating conditions should match design specifications. Exceeding rated loads, speeds, or temperature limits accelerates wear regardless of bearing quality. Ensuring applications remain within design parameters maximizes service life and maintains performance standards.

Sourcing & Authenticity – How to Get Genuine 2RSB9053 Bearings

Verifying authenticity protects against counterfeit components that could jeopardize system reliability. Reputable suppliers provide documentation confirming the bearing’s origin and specifications. Manufacturer datasheets should accompany purchases, offering detailed information about materials, tolerances, and performance characteristics.

Established distributors maintain relationships with recognized manufacturers. These suppliers understand the importance of authenticity and implement quality control measures throughout their supply chains. Building relationships with trusted distributors reduces the risk of receiving substandard components.

Price comparisons should consider value rather than just cost. Unusually low prices often signal counterfeit products or seconds that didn’t meet quality standards. While budget constraints exist in every project, the cost of bearing failure—including downtime, repairs, and potential safety issues—far exceeds the savings from purchasing cheap components.

Certification standards provide objective quality measures. Bearings manufactured to ISO standards undergo rigorous testing to verify performance claims. Certifications demonstrate commitment to quality and ensure that components will perform as specified.

Physical inspection reveals quality indicators. Genuine bearings exhibit consistent surface finishes, precise markings, and proper packaging. Rough edges, inconsistent engraving, or generic packaging might indicate counterfeit products.

Future Trends – Why 2RSB9053 Matters Even More Tomorrow

Advanced materials research continues to improve bearing performance. New alloys and ceramic materials promise even better wear resistance and higher temperature tolerance. While these innovations may lead to new bearing designs, the fundamental principles embodied in the 2RSB9053 will remain relevant.

Smart bearing technology integrates sensors directly into bearing assemblies. These intelligent components monitor their own condition, transmitting data about temperature, vibration, and load. While the 2RSB9053 itself is a mechanical component, future versions might incorporate such technology for predictive maintenance applications.

Sustainability considerations influence component design and selection. Long-lasting, reliable bearings like the 2RSB9053 contribute to sustainability by reducing replacement frequency and associated waste. Energy-efficient operation also aligns with broader goals of reducing power consumption across industrial systems.

Electric vehicle expansion creates new opportunities for precision bearings. As the automotive industry shifts toward electric powertrains, demand grows for bearings that can handle the unique requirements of electric motors and transmissions. The proven design principles of the 2RSB9053 position similar components well for these emerging applications.

Manufacturing automation increases demand for reliable components. As factories implement more automated systems, the need for bearings that operate continuously without frequent maintenance becomes even more critical. Components with sealed designs and long service lives will become increasingly valuable in these environments.

Conclusion

The 2RSB9053 represents more than just a bearing—it embodies decades of engineering refinement focused on delivering reliable, efficient performance. Its double-sealed design protects internal components while minimizing maintenance requirements. The deep-groove configuration handles diverse loads while maintaining smooth operation. Applications spanning aerospace, automotive, robotics, and consumer products all benefit from what this component offers.

Understanding technical specifications helps professionals make informed selection decisions. Proper installation techniques ensure the bearing performs to its full potential. While the sealed design simplifies maintenance, regular monitoring still provides valuable insights into system health. Sourcing genuine components from reputable suppliers protects against the risks associated with counterfeits.

Looking forward, the principles demonstrated by the 2RSB9053 will continue influencing bearing design as new materials and technologies emerge. Whether in traditional industrial applications or emerging sectors like electric vehicles and advanced robotics, the need for precise, reliable bearings remains constant. This component has proven its worth across countless applications, and its legacy will inform engineering decisions for years to come.

For more information, visit Digi Magazine.