Modern roofing has changed dramatically, with homeowners and businesses searching for materials that are lightweight, durable, energy-efficient, and visually appealing. Among the most exciting options available today is acryldach, a revolutionary acrylic-based roofing solution that combines strength, clarity, and weather resistance in one package. Whether you are looking for transparent roofing panels for a greenhouse, stylish skylights for your home, or long-lasting coatings for flat roofs, acryldach offers an impressive balance of practicality and elegance. This comprehensive guide explains what acryldach is, why it has become popular, and how it compares to traditional roofing materials like polycarbonate, glass, and fiberglass.

Acryldach is a durable roofing solution crafted from PMMA acrylic, valued for its strength, clarity, and resistance to tough weather. In simple terms, acryldach can refer to acrylic roofing panels used in skylights, pergolas, or greenhouses, as well as liquid-applied acrylic roof coatings that provide a waterproof and reflective barrier for flat and low-slope roofs. Because of this versatility, acryldach has quickly gained popularity in residential, commercial, and agricultural construction.

One reason behind the rise of acryldach roofing is its ability to combine the beauty of glass with the toughness of synthetic materials. Unlike traditional glass, which can shatter easily, acryldach panels are impact-resistant and much lighter, making them easier to install and maintain. Furthermore, the transparency of clear roof panels ensures maximum daylight penetration, reducing reliance on artificial lighting and lowering energy costs. In addition, acrylic roof coatings provide waterproofing and UV protection, ensuring long-term durability and reducing maintenance expenses. These qualities make acryldach not just a roofing material, but a smart investment for the future.

What Does Acryldach Mean?

The term “acryldach” originates from German, where “acryl” refers to acrylic material and “dach” means roof. Together, the term represents roofing systems made primarily from acrylic polymers. This terminology has gained international recognition as builders and architects worldwide appreciate the unique properties that acrylic materials bring to roofing applications.

In practical terms, acryldach encompasses two main categories of products. First, there are solid acrylic panels, often called acrylite sheet products, which serve as transparent or translucent roofing elements. Second, there are liquid acrylic coatings that professionals apply directly to existing roof surfaces to create a seamless, waterproof membrane. Both categories share common benefits such as weather resistance, UV stability, and excellent optical properties, yet they serve different functional purposes in construction projects.

Understanding what acryldach means helps property owners make informed decisions about which type of acrylic roofing solution best fits their specific needs. Whether someone requires natural lighting for an indoor space or needs a protective coating for an aging flat roof, acryldach technology offers reliable solutions.

Acrylic Panels vs. Acrylic Roof Coatings

While both acrylic panels and acrylic roof coatings fall under the acryldach umbrella, they serve distinct purposes and have different installation requirements. Recognizing these differences ensures that property owners select the right product for their roofing project.

Acrylic Roofing Panels

Acrylic panels, including acrylite sheet products, are solid sheets manufactured from PMMA (polymethyl methacrylate) material. These panels come in various thicknesses, colors, and profiles such as flat, corrugated, or multiwall designs. Builders typically use them for skylights, canopies, pergola covers, and greenhouse roofs where natural light transmission is desired. The panels attach to structural frames using specialized mounting hardware and require proper sealing to prevent water infiltration.

The main advantages of acrylic panels include excellent clarity, impact resistance, and thermal stability. They maintain their transparency over time without yellowing significantly when properly manufactured with UV stabilizers. Installation involves cutting panels to size, drilling mounting holes, and securing them to supporting structures with appropriate fasteners and weatherproof gaskets.

Acrylic Roof Coatings

In contrast, acrylic roof coatings are liquid-applied products that professionals spray, roll, or brush onto existing roof surfaces. These coatings cure to form a seamless, flexible membrane that provides waterproofing, UV reflection, and thermal protection. They work particularly well on flat or low-slope roofs made from materials like modified bitumen, metal, concrete, or single-ply membranes.

The primary benefits of acrylic coatings include ease of application, excellent reflectivity that reduces cooling costs, and the ability to extend the life of aging roofs without complete replacement. Unlike panels that require structural support, coatings simply need a clean, properly prepared substrate. Maintenance typically involves periodic recoating every several years to maintain optimal performance.

Types of Acryldach Roofing Solutions

Acryldach technology encompasses several product types, each designed for specific applications and performance requirements. Understanding these options helps buyers choose the most suitable solution for their roofing needs.

Acryldach Acrylic Roof Panels (PMMA Sheets)

Standard acrylic panels, also known as PMMA sheets or acrylite sheet products, represent the most common form of transparent roofing. Manufacturers produce these solid sheets in various thicknesses ranging from 2mm to 25mm, with thicker options providing greater strength and insulation properties. Clear panels offer maximum light transmission of up to 92%, while tinted versions reduce glare and heat gain.

These panels excel in applications where optical clarity matters most. Architects frequently specify them for residential skylights, museum atriums, shopping mall canopies, and transit shelters. The material’s inherent UV resistance prevents degradation from sunlight exposure, ensuring long-lasting performance even in harsh climates. Additionally, acrylic panels weigh significantly less than glass alternatives, reducing structural load requirements and installation complexity.

Corrugated Acryldach Roofing Sheets

Corrugated acrylic sheets feature a wavy profile that adds structural rigidity while maintaining light transmission properties. This design allows for greater spans between support members compared to flat panels, making them cost-effective for large coverage areas. The corrugation pattern also facilitates water runoff, preventing pooling and reducing the risk of leaks.

Common applications for corrugated acryldach include patio covers, carports, agricultural buildings, and industrial skylights. The sheets typically come in standard profiles that match metal roofing systems, allowing for mixed-material installations. Property owners appreciate how corrugated panels combine functionality with aesthetic appeal, creating protected outdoor spaces that remain bright and inviting.

Multiwall / Twinwall Acryldach Panels

Multiwall acrylic panels feature a hollow structure with internal ribs connecting two or more outer walls. This design creates air chambers that significantly improve thermal insulation compared to solid sheets. Twin-wall panels contain one air layer, while triple-wall and quad-wall options offer progressively better insulation values.

These panels suit applications where temperature control matters, such as conservatories, commercial greenhouses, and climate-controlled walkways. The cellular structure reduces heat loss in winter and heat gain in summer, lowering energy costs for heating and cooling. Despite their superior insulation, multiwall panels maintain good light transmission, though slightly less than solid sheets due to the internal ribs. Their lighter weight and higher strength-to-weight ratio make them easier to handle and install than solid panels of equivalent thickness.

Liquid-Applied Acryldach Coatings

Liquid acrylic roofing coatings represent a different approach to acryldach technology. These white or light-colored coatings reflect solar radiation, reducing roof surface temperatures by up to 50 degrees compared to dark, uncoated surfaces. Lower temperatures extend roof membrane life and dramatically decrease air conditioning expenses in warm climates.

Professional contractors typically apply these coatings in multiple layers, starting with a primer, followed by base coats embedded with reinforcing fabric at seams and penetrations, and finishing with topcoats that provide UV protection and weather resistance. The resulting membrane remains flexible, accommodating building movement without cracking. Acrylic coatings work well for restoration projects, allowing building owners to extend their roof’s service life by 10-15 years without the expense and disruption of complete replacement.

Materials & Technology Behind Acryldach

Understanding the materials and manufacturing processes behind acryldach products helps explain their superior performance characteristics and long-term reliability.

PMMA (Polymethyl Methacrylate) Explained

PMMA, the primary material in acrylic panels, is a transparent thermoplastic polymer known commercially as acrylic glass or by brand names like acrylite sheet. Chemically, it consists of methyl methacrylate units polymerized into long chains. This molecular structure gives PMMA exceptional optical clarity, high light transmission, and excellent weathering resistance.

Manufacturers produce PMMA sheets through two main processes: extrusion and cell casting. Extruded sheets are more economical and suitable for most applications, while cell-cast sheets offer superior optical quality and better dimensional stability for demanding uses. Both processes can incorporate additives like UV absorbers, impact modifiers, and colorants to enhance specific properties.

The versatility of PMMA allows producers to create various sheet types, from solid panels to multiwall structures, all while maintaining the material’s inherent benefits. Its relatively low density compared to glass results in lightweight panels that simplify handling and installation. Additionally, PMMA’s thermal formability enables manufacturers to create curved or shaped panels for architectural applications.

UV Stabilizers & Weather Resistance

One critical factor determining acryldach longevity is the inclusion of UV stabilizers in the acrylic formulation. Sunlight contains ultraviolet radiation that can gradually degrade polymers, causing yellowing, brittleness, and loss of mechanical properties. High-quality acryldach products incorporate specialized UV absorbers and stabilizers that protect the material from this damage.

These additives work through different mechanisms. UV absorbers capture harmful radiation and convert it to harmless heat, while hindered amine light stabilizers (HALS) neutralize free radicals formed during UV exposure. Together, they dramatically slow the aging process, allowing properly manufactured acryldach panels to maintain their clarity and strength for decades.

Weather resistance extends beyond UV protection. Acrylic materials naturally resist moisture absorption, preventing dimensional changes and maintaining structural integrity in humid conditions. They also withstand temperature extremes from -40°C to +80°C without significant property changes. This combination of UV and environmental resistance makes acryldach suitable for challenging climates worldwide.

Colors, Textures, and Finish Options

Modern acryldach products come in an impressive array of aesthetic options, allowing designers and property owners to achieve their desired visual effects while maintaining functional performance.

Color options range from crystal clear for maximum light transmission to various tints like bronze, gray, and green that reduce glare and heat gain. Opaque colors provide privacy while still allowing diffused light transmission. Manufacturers can also produce panels with special effects like opal finishes for light diffusion or mirror coatings for decorative applications.

Texture choices include smooth surfaces for optical clarity, frosted or satin finishes for privacy and light diffusion, and prismatic patterns that enhance light distribution. Some products feature embossed textures that add visual interest while maintaining adequate light transmission.

Surface finishes may include standard glossy surfaces, matte treatments, or specialized coatings that provide additional benefits like anti-fog properties, easy cleaning, or enhanced scratch resistance. These options allow acryldach to suit various architectural styles and functional requirements, from contemporary minimalist designs to traditional aesthetic preferences.

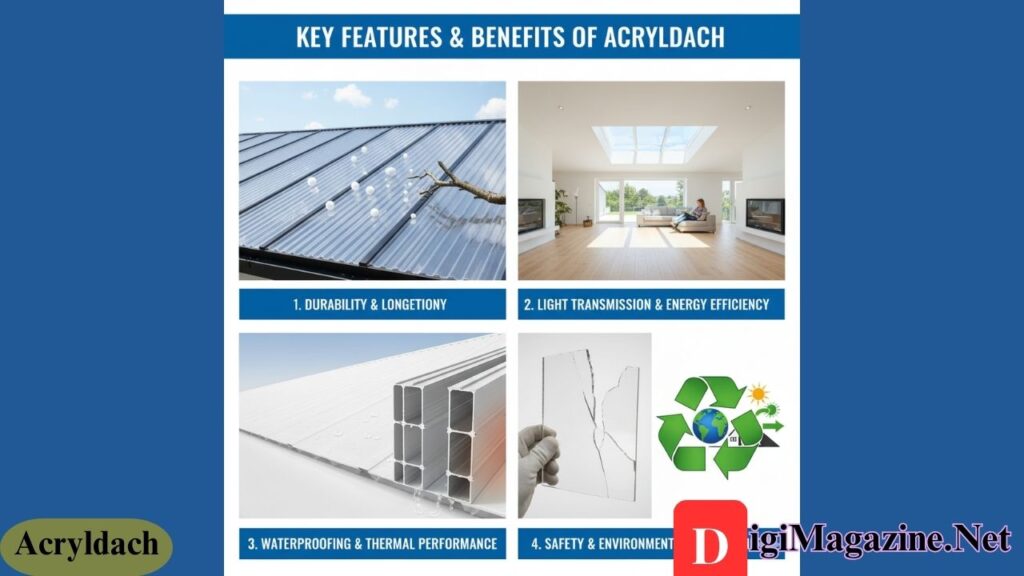

Key Features & Benefits of Acryldach

Acryldach roofing solutions offer numerous advantages that explain their growing popularity among property owners, architects, and builders.

Durability & Longevity

One of the most compelling reasons to choose acryldach is its exceptional durability. High-quality acrylic panels can last 25-30 years or more with proper maintenance, while acrylic roof coatings typically provide 10-15 years of reliable protection before requiring renewal. This longevity comes from the material’s inherent resistance to environmental factors that degrade lesser materials.

Impact resistance represents another durability advantage. Acrylic panels are significantly tougher than glass, resisting breakage from hail, falling branches, and other impacts. This characteristic makes them ideal for exposed locations where damage risk is higher. Even when damaged, acrylic cracks rather than shattering into dangerous shards, improving safety.

The material’s dimensional stability ensures that panels maintain their shape and fit over time. Unlike some plastics that warp or sag under heat and load, properly manufactured acryldach products retain their structural integrity throughout their service life. This stability reduces maintenance needs and preserves the roof’s weathertight performance.

Light Transmission & Energy Efficiency

Light transmission stands as one of acryldach’s defining characteristics. Clear acrylic panels transmit up to 92% of visible light, rivaling or exceeding glass performance. This exceptional transparency allows maximum natural daylight penetration, creating bright, pleasant interior spaces that reduce dependence on artificial lighting.

The energy savings from increased daylighting can be substantial. Studies show that replacing electric lighting with natural light during daytime hours can reduce lighting energy consumption by 50-75% in spaces with adequate daylighting design. For commercial buildings, this translates to lower operating costs and reduced carbon footprints.

Beyond daylighting benefits, acrylic roof coatings provide significant cooling cost reductions. Their highly reflective white surface bounces solar radiation back into the atmosphere rather than allowing it to heat the building. This cool roof effect can lower air conditioning costs by 20-30% in warm climates, with payback periods often under three years.

Waterproofing & Thermal Performance

Waterproofing ranks among the primary functions of any roofing system, and acryldach excels in this area. Solid panels, when properly installed with appropriate sealing and flashing, create watertight barriers that prevent leaks. The material itself does not absorb water, maintaining its properties even in constantly wet conditions.

Liquid acrylic coatings provide even more comprehensive waterproofing by creating seamless membranes without joints or fastener penetrations that could leak. The coating’s flexibility allows it to accommodate building movement and thermal expansion without cracking, maintaining its waterproof integrity through temperature cycles and structural shifts.

Thermal performance varies depending on the specific acryldach product. Solid single-layer panels provide minimal insulation, making them suitable where thermal control is less critical. Multiwall panels offer much better insulation values, with twin-wall products typically achieving R-values around 1.7-2.0, and thicker multi-wall options reaching R-3.0 or higher. For comparison, single-pane glass has an R-value of approximately 0.9, showing the improvement that multiwall acrylic provides.

Safety & Environmental Friendliness

Safety considerations make acryldach attractive for public and residential applications. Unlike glass, which shatters into sharp fragments, acrylic fractures into larger, less dangerous pieces. This characteristic reduces injury risk in the event of breakage from impacts or other causes. Additionally, acrylic’s light weight reduces the risk of serious injury if panels do fall during installation or severe weather events.

Fire safety represents another consideration. While acrylic is combustible, modern formulations include fire-retardant additives that improve performance. Many acryldach products meet building code requirements for Class B or Class C fire ratings when tested according to ASTM E84. However, local codes vary, so specifiers should verify requirements for their specific application.

Environmental friendliness is increasingly important to property owners and builders. Acrylic materials are recyclable, and some manufacturers operate take-back programs for old panels. The energy savings from daylighting and reflective coatings reduce fossil fuel consumption and greenhouse gas emissions over the product’s lifetime. Additionally, acrylic production generally has a lower environmental impact than glass manufacturing, which requires higher processing temperatures.

The material’s longevity also contributes to sustainability by reducing replacement frequency and the associated resource consumption and waste generation. When acryldach roofing reaches end-of-life, responsible recycling can recover the material for use in other applications, closing the sustainability loop.

Acryldach vs Alternatives

Comparing acryldach to other transparent and translucent roofing materials helps clarify when it represents the best choice and when alternatives might be preferable.

Acryldach vs Polycarbonate Roofing

Polycarbonate represents acryldach’s closest competitor in the transparent roofing market. Both materials offer impact resistance, light weight, and good weather resistance, yet important differences exist.

Optical clarity favors acryldach significantly. Acrylic maintains better transparency throughout its life, while polycarbonate tends to yellow more noticeably over time despite UV protection. For applications where appearance and maximum light quality matter, acryldach provides superior long-term performance.

Impact resistance strongly favors polycarbonate, which is virtually unbreakable under normal conditions. This makes polycarbonate preferred for vandalism-prone locations or areas subject to extreme impact hazards. However, for most residential and commercial applications, acrylic’s impact resistance proves more than adequate.

Scratch resistance benefits acryldach, as acrylic surfaces are harder and more resistant to surface damage than polycarbonate. This characteristic helps acryldach panels maintain their clarity and appearance longer, particularly in applications where surface contact occurs during cleaning or other maintenance.

Price typically favors polycarbonate slightly, though differences narrow for premium UV-stabilized versions of both materials. The choice often comes down to whether optical quality or maximum impact resistance takes priority for the specific application.

Acryldach vs Glass Roofing

Glass has served as the traditional choice for transparent roofing for centuries, but acryldach offers compelling advantages that have captured market share in recent decades.

Weight represents one of acryldach’s most significant advantages. Acrylic panels weigh roughly half what glass panels of equivalent thickness weigh. This reduced weight simplifies structural requirements, eases handling during installation, and reduces shipping costs. For retrofit applications, lighter acryldach may work with existing structures that cannot support the weight of glass.

Safety strongly favors acryldach due to its fracture behavior. When glass breaks, it creates dangerous sharp fragments, while acrylic produces larger, less hazardous pieces. Building codes increasingly recognize this safety advantage, particularly for overhead glazing applications.

Thermal insulation benefits acryldach, especially multiwall products. Even solid acrylic provides better insulation than single-pane glass, while multiwall acrylic can match or exceed insulated glass unit (IGU) performance at lower cost and weight.

Glass maintains some advantages, including superior scratch resistance, complete fire resistance, and the prestige associated with traditional glass architecture. For heritage restoration or high-end architectural applications, glass may remain preferred despite acryldach’s practical benefits.

Acryldach vs Fiberglass Roofing

Fiberglass (also called GRP – glass-reinforced polyester) offers another translucent roofing option, though it serves somewhat different applications than acryldach.

Clarity strongly favors acryldach, as fiberglass cannot match acrylic’s transparency. Fiberglass panels are translucent rather than transparent, providing light without clear views. This makes fiberglass suitable where privacy matters but limits its use where visibility is desired.

Light transmission quality differs significantly. While fiberglass transmits substantial light, it tends to yellow more rapidly than properly stabilized acryldach. The fiberglass matrix also scatters light differently, producing a softer, more diffused illumination compared to acryldach’s clearer, more directed light.

Strength characteristics favor fiberglass for heavily loaded applications. The glass fiber reinforcement provides excellent strength and rigidity, allowing fiberglass panels to span longer distances or support greater loads than acrylic of similar thickness.

Chemical resistance benefits fiberglass in industrial environments where corrosive substances may contact the roof. Acryldach performs well in normal environments but can be attacked by certain solvents and chemicals that fiberglass resists.

Cost generally favors fiberglass, particularly for industrial applications where optical clarity is less important. However, when appearance, light quality, and longevity matter most, acryldach justifies its higher initial investment.

Applications of Acryldach

The versatility of acryldach technology enables its use across numerous construction sectors and applications.

Residential Uses (Patios, Pergolas, Skylights)

Homeowners increasingly discover acryldach benefits for various residential applications. Patio covers and pergola roofs represent popular uses, creating comfortable outdoor living spaces protected from rain while remaining bright and open. The material’s light weight allows homeowners to add covered areas without extensive structural modifications, and transparent or tinted panels maintain the sense of being outdoors while providing weather protection.

Skylights constitute another common residential application. Acryldach skylights flood interior rooms with natural light, transforming dark spaces into bright, inviting areas. The material’s impact resistance provides peace of mind regarding hail and debris, while its insulating properties (particularly multiwall versions) help control solar heat gain and reduce energy costs.

Sunrooms and conservatories benefit from acryldach’s combination of transparency and thermal performance. These spaces require maximum light transmission to create the desired bright, greenhouse-like atmosphere, yet they also need adequate insulation to remain comfortable and energy-efficient. Multiwall acryldach panels strike an excellent balance between these competing requirements.

Pool enclosures represent specialized residential applications where acryldach excels. The material’s moisture resistance prevents degradation in humid environments, while transparency allows swimmers to enjoy views and natural light. Safety considerations favor acryldach over glass for this application, as broken fragments pose less injury risk if accidents occur.

Commercial Uses (Warehouses, Canopies, Malls)

Commercial properties employ acryldach for both functional and aesthetic purposes. Warehouse skylights reduce the need for daytime artificial lighting, cutting energy costs while improving working conditions. The durability of acryldach ensures long-term performance with minimal maintenance, important for facilities where access may be difficult or disruptive.

Building canopies and covered walkways benefit from acryldach’s weather resistance and visual appeal. Shopping centers, office complexes, and transit stations use transparent or tinted panels to create protected circulation areas that feel open and inviting. The material’s light weight simplifies the design and construction of these features, often allowing them to be added to existing structures without major reinforcement.

Retail environments increasingly incorporate acryldach for architectural features like atriums, domed skylights, and interior partitions. The material’s clarity creates dramatic spaces flooded with natural light, which studies show increases customer dwell time and purchasing behavior. Mall developers particularly value how acryldach features differentiate their properties while reducing operating costs through daylighting.

Restaurant outdoor seating areas represent another commercial application where acryldach shines. Weather-protected patio spaces extend the usable outdoor season while keeping diners comfortable. Transparent or lightly tinted roofing maintains the al fresco atmosphere customers seek while protecting them from sun and rain.

Agricultural Uses (Greenhouses, Farms)

Agriculture represents a major market for acryldach products, particularly for greenhouse construction. The material’s high light transmission ensures that crops receive maximum solar radiation for photosynthesis, promoting healthy growth and high yields. Compared to glass greenhouses, acryldach structures cost less to build, install faster, and provide better insulation when using multiwall panels.

Commercial growers appreciate how multiwall acryldach panels reduce heating costs during cold months while moderating temperature swings between day and night. The improved thermal stability creates more consistent growing conditions, reducing plant stress and improving crop quality. Additionally, the impact resistance of acryldach protects valuable plants and equipment from hail damage that could destroy glass-covered structures.

Livestock facilities sometimes employ acryldach for barn skylights or translucent roof sections. Natural lighting improves animal welfare and reduces the need for electric lighting during daylight hours. The material’s resistance to ammonia and moisture makes it suitable for these challenging environments.

Equipment storage buildings benefit from acryldach skylights that provide illumination for machinery maintenance and repair work without requiring electric lights. The light weight and durability of the material ensure long service life even in agricultural environments where equipment impacts or flying debris might occur.

Acryldach Installation Guide

Proper installation ensures that acryldach products deliver their full performance potential and long service life.

Tools & Materials Needed

Installing acrylic panels requires specific tools and materials. Essential cutting tools include circular saws with fine-toothed blades designed for plastics, or scoring knives for thinner sheets. Drilling requires sharp twist bits or specialized plastic-drilling bits to create clean holes without cracking. Measuring tools, including tape measures, squares, and levels, ensure accurate fitting and alignment.

Fastening systems vary depending on the installation type. Screws with neoprene or EPDM washers create weathertight connections while allowing thermal expansion. Special plastic button caps or decorative covers hide screw heads for improved appearance. Structural aluminum or steel profiles provide edge support and weather sealing for panel systems.

Sealing materials are crucial for weatherproofing. Neutral-cure silicone sealants designed for plastic compatibility work well for most applications. Butyl tape provides an alternative for horizontal seam sealing. EPDM or neoprene gaskets seal panels against support frames while accommodating movement.

For liquid acrylic coating installations, equipment needs differ significantly. Airless sprayers represent the most efficient application method for large areas, while smaller projects may use rollers or brushes. Surface preparation requires pressure washers, scrapers, and primers specific to the substrate type. Mixing equipment ensures proper coating consistency, and safety gear protects applicators from overspray.

DIY Installation Tips

Homeowners with basic construction skills can successfully install acryldach panels for many residential applications. Planning represents the critical first step. Accurate measurements prevent waste and ensure proper fit. Allowing for thermal expansion is essential, typically requiring gaps of 3-5mm per meter of panel length. This spacing prevents buckling or cracking when temperatures change.

Cutting acrylic requires care to avoid chips and cracks. Leaving protective film in place during cutting protects surfaces from scratches. Using sharp blades and moderate feed speeds produces clean cuts. For curved cuts, jigsaws with fine blades work well. After cutting, edges should be smoothed with fine sandpaper to prevent stress concentrations.

Drilling techniques significantly affect installation success. Pilot holes prevent cracking, and using drill speeds of 500-1000 RPM reduces heat buildup that can cause melting. Holes should be slightly larger than fastener diameters to allow thermal movement. Never overtighten fasteners, as this can crack panels or prevent expansion.

Sealing requires attention to detail for weatherproof results. Clean all surfaces thoroughly before applying sealants or tapes. Apply continuous, generous beads of sealant to ensure complete coverage without gaps. Smooth sealant with a wet finger or tool to improve appearance and adhesion. Allow adequate cure time before exposing joints to water.

Safety considerations include wearing eye protection when cutting and drilling, handling large panels carefully to avoid breaking, and working with helpers for panels larger than can be safely managed alone. Avoiding work during windy conditions prevents panels from acting as sails and causing accidents.

Professional Installation: What to Expect

For complex installations or when warranty requirements mandate professional work, understanding the process helps property owners prepare. Professional installers begin with site assessment to verify structural adequacy, identify potential complications, and confirm measurements. This planning phase prevents surprises that could delay completion or increase costs.

Material delivery typically occurs shortly before installation to minimize storage requirements and potential damage. Professionals have equipment to safely unload and handle large or heavy shipments. They verify quantities and inspect for damage before accepting materials.

The installation process starts with surface preparation. Existing surfaces must be clean, dry, and structurally sound. Professionals repair or replace damaged substrate areas before proceeding. They install flashing, edge trim, and support members according to manufacturer specifications and building codes.

Panel installation follows systematic patterns that ensure proper overlap, alignment, and weatherproofing. Professionals work methodically, securing panels progressively while checking alignment and addressing issues immediately. They apply sealants correctly and install closures or trim pieces that complete the weather barrier.

Quality inspections occur during and after installation. Professionals check for proper fastener spacing, adequate sealing, correct slopes for drainage, and overall workmanship. They clean panels, remove protective films, and provide maintenance instructions to property owners.

For liquid acrylic coating installations, professionals follow multi-step processes. Surface preparation includes pressure washing, making repairs, and applying primers. Base coats are applied with reinforcing fabric embedded at seams, penetrations, and detail areas. Additional coats build proper thickness, and final topcoats provide UV protection and aesthetic finish. Professionals monitor weather conditions throughout, as temperature and humidity affect coating performance.

Maintenance & Care of Acryldach Roofs

Proper maintenance extends acryldach service life and maintains its appearance and performance.

Cleaning & Preventing Yellowing

Regular cleaning keeps acryldach panels looking their best and functioning properly. Mild soap or detergent mixed with water provides effective cleaning without damaging surfaces. Application with soft cloths or non-abrasive sponges removes dirt and debris without scratching. Thoroughly rinsing with clean water prevents residue buildup that can attract more dirt.

Avoiding harsh chemicals protects acrylic surfaces. Solvents, abrasive cleaners, and ammonia-based products can cause crazing, clouding, or softening. Even some window cleaners contain chemicals that damage acrylics, so checking product compatibility before use is important. When in doubt, testing cleaners on inconspicuous areas prevents widespread damage.

Preventing yellowing requires selecting properly UV-stabilized products initially and protecting surfaces from chemical exposure. While high-quality acryldach resists yellowing for decades, inferior products without adequate stabilizers yellow quickly. Once yellowing occurs, it cannot be reversed, only replaced. Regular cleaning removes pollutants that could accelerate degradation.

Tree sap, bird droppings, and other organic deposits should be removed promptly, as they can stain or etch surfaces if left too long. Gentle scraping with plastic scrapers followed by cleaning usually removes these deposits without damage. Reapplying approved wax or polish can help protect surfaces between cleanings.

Repairing Cracks & Leaks

Minor damage sometimes occurs despite acryldach’s durability. Small cracks can be repaired using specialized acrylic cements that chemically bond to the material. Cleaning the crack thoroughly and applying cement according to manufacturer instructions creates nearly invisible repairs. Larger cracks may require patching with pieces of matching material bonded in place.

Leaks typically result from sealant failure, loose fasteners, or damaged panels. Identifying the leak source represents the first troubleshooting step. Water may travel along panels before dripping, making the visible leak location distant from the actual entry point. Systematic inspection during rain or using a hose test helps pinpoint problems.

Resealing joints addresses many leak issues. Removing old, failed sealant completely ensures that new material bonds properly. Cleaning surfaces thoroughly and allowing them to dry before applying fresh sealant creates durable repairs. Using high-quality sealants formulated for acrylic compatibility provides long-lasting results.

Replacing damaged fastener washers or tightening loose connections fixes some leaks. However, overtightening can crack panels, so gradual, careful adjustment is necessary. If washers have deteriorated, replacing them with new ones restores the weathertight seal.

Panel replacement becomes necessary when damage exceeds repair capabilities. Fortunately, acryldach’s modular nature usually allows replacing individual damaged panels without disturbing surrounding undamaged ones. Matching replacement panels to existing ones in type, thickness, and color ensures consistent appearance.

Seasonal Maintenance Checklist

Implementing seasonal maintenance routines prevents problems and extends acryldach life. Spring maintenance focuses on removing winter debris, checking for damage from ice or storms, and cleaning panels after months of weather exposure. Inspecting sealants and flashings identifies areas needing attention before summer rains.

Summer maintenance emphasizes cleaning to remove pollen, dust, and other accumulated debris that reduces light transmission. Checking for proper drainage ensures that summer thunderstorms don’t cause water pooling or backup. Inspecting fasteners and connections verifies that thermal expansion and contraction haven’t loosened anything.

Fall preparation includes thorough cleaning to remove leaves and organic matter that could stain panels or clog drainage. Trimming overhanging branches prevents damage from falling limbs during winter storms. Inspecting sealants provides an opportunity to make repairs before winter weather makes work difficult.

Winter monitoring watches for excessive snow accumulation on low-slope applications. While acryldach withstands normal snow loads, removing excessive buildup prevents potential damage. Checking that drainage remains clear prevents ice dams. Avoiding walking on panels during freezing conditions protects against cracking from impact on cold-brittled material.

For liquid acrylic coatings, seasonal inspections look for coating degradation, blistering, or areas where recoating may be approaching. Most coatings require renewal every 5-10 years, depending on climate and sun exposure. Planning for recoating prevents allowing coatings to fail, which would require more extensive repairs.

Acryldach Cost & ROI

Understanding acryldach costs and return on investment helps property owners make informed purchasing decisions.

Price Per Square Meter (Panels & Coatings)

Acrylic panel prices vary widely depending on type, thickness, and features. Standard clear sheets in common thicknesses (3-6mm) typically cost between $20-50 per square meter for basic extruded products. Premium cell-cast acrylite sheet products with superior clarity and UV protection range from $40-80 per square meter. Thicker panels command proportionally higher prices due to increased material content.

Corrugated and multiwall panels generally fall in the $25-70 per square meter range depending on profile, wall structure, and thickness. Specialty products with specific colors, textures, or enhanced properties cost more than standard clear panels. Installation hardware, profiles, and sealants add approximately 15-30% to material costs.

Professional installation labor varies by region and project complexity but typically adds $15-40 per square meter. Complex projects with many angles, penetrations, or detail work push costs toward the higher end. DIY installation eliminates labor costs but requires tool investment and time.

Liquid acrylic coating costs depend on substrate condition and coating system specifications. Material costs range from $2-8 per square meter for coating alone, with complete installed systems (including preparation,Retry

A

Continue

primer, base coats, and topcoats) typically costing $15-35 per square meter. Roofs requiring extensive repairs before coating application increase costs significantly, while roofs in good condition requiring only cleaning fall toward the lower end.

Comparing these costs to alternatives helps contextualize value. Glass roofing typically costs $50-150 per square meter installed, making acryldach considerably more economical. Polycarbonate ranges from $15-50 per square meter, offering similar or slightly lower pricing than acryldach. Complete roof replacement with conventional materials like asphalt shingles or metal costs $80-200 per square meter, making acrylic coatings an attractive alternative for extending existing roof life.

Energy Savings & Long-Term Value

The return on investment for acryldach extends beyond initial costs to include substantial energy savings over the product’s lifetime. Daylighting from transparent panels reduces electric lighting needs by 50-75% in well-designed applications. For a commercial building using $5,000 annually for daytime lighting, this translates to $2,500-3,750 in savings each year.

Reflective acrylic coatings generate impressive cooling cost reductions. Studies document energy savings of 20-30% for air conditioning in buildings with coated roofs. A facility spending $10,000 annually on cooling could save $2,000-3,000 per year with proper coating application. These savings continue throughout the coating’s 10-15 year service life, accumulating to $20,000-45,000 in total benefits.

Thermal performance from multiwall panels reduces both heating and cooling costs. While exact savings depend on climate and building characteristics, typical reductions of 15-25% for temperature control costs are achievable. Over a 25-year panel lifespan, these savings can exceed the initial panel investment multiple times.

Maintenance cost reductions contribute to long-term value. Acryldach requires less maintenance than many alternatives, with simple cleaning representing the primary recurring expense. Avoided costs for repainting, sealing, or frequent repairs add to overall value. For liquid coatings, avoiding complete roof replacement saves tens of thousands of dollars while extending asset life.

Property value improvements from acryldach installations may also contribute to ROI. Natural lighting from skylights increases interior appeal and functionality, potentially boosting resale values. Energy-efficient features like reflective coatings attract environmentally conscious buyers and reduce operating costs for income properties, improving cash flow and property values.

Typical payback periods range from 3-8 years for energy-focused acryldach applications like reflective coatings or daylighting panels in commercial settings. Residential applications focused more on aesthetics or comfort may have longer payback periods but still provide value through improved livability and eventual energy savings.

Factors Affecting Cost

Multiple variables influence final acryldach project costs. Project size represents a major factor, with larger installations benefiting from economies of scale for both materials and labor. Purchasing panels by the pallet rather than individual sheets reduces per-unit costs. Labor efficiency improves on large projects as workers develop familiarity with the specific installation.

Site accessibility affects labor costs significantly. Easily accessible locations with good staging areas allow efficient work, while difficult access or multistory installations require additional time and equipment. Safety equipment needs for high or steep roofs add both direct costs and labor time.

Product specifications impact pricing substantially. Standard clear panels cost less than specialty colors, textures, or enhanced features. Thicker panels, while providing greater strength and insulation, cost more than thinner alternatives. Premium acrylite sheet products command prices significantly above basic extruded panels.

Existing condition strongly influences coating project costs. Roofs in good condition requiring only cleaning and coating proceed quickly and economically. Roofs with damage, leaks, or deteriorated surfaces need extensive preparation, repairs, and potentially partial replacement before coating, dramatically increasing costs.

Geographic location affects both material and labor pricing. Urban areas typically have higher labor rates but better material availability and competitive pricing. Rural locations may face higher material transport costs but potentially lower labor rates. Regional climate influences product selection, with specialized features for extreme conditions adding costs.

Permitting and regulatory requirements vary by jurisdiction. Some locations require permits, inspections, and compliance with specific codes that add administrative costs and potential design modifications. Understanding local requirements during planning prevents budget-busting surprises.

Warranty expectations influence costs when professional installation is required. Extended warranties or specialized coverage may require using certified installers, specific product brands, or enhanced installation techniques that increase upfront expenses while providing long-term protection.

Top Acryldach Brands & Suppliers

Selecting quality products from reputable manufacturers ensures optimal acryldach performance and longevity. Several major brands dominate the acrylic roofing market, each offering distinct product lines and characteristics.

Leading acrylite sheet manufacturers include established names recognized worldwide for quality and innovation. These companies invest heavily in research and development, continuously improving UV stabilization, impact resistance, and optical properties. Their products typically carry comprehensive technical documentation, installation guidelines, and warranty support.

European manufacturers have particularly strong reputations for premium acrylic panels, often producing cell-cast sheets with exceptional clarity and dimensional stability. These products suit demanding architectural applications where appearance and performance are paramount. While they command premium prices, their longevity and beauty justify the investment for many projects.

North American suppliers offer excellent value propositions, combining good quality with competitive pricing and local availability. Their product ranges typically include both economy and premium options, allowing buyers to match products to budgets and performance requirements. Strong distribution networks ensure ready availability and reasonable delivery times.

Asian manufacturers have expanded their presence in global markets, offering competitive pricing for standard products. Quality varies considerably among producers, making careful specification and verification important. Reputable Asian brands can provide excellent value, particularly for larger projects where budget constraints matter.

Liquid acrylic coating manufacturers include specialized companies focused specifically on roof coatings as well as broader paint and coatings companies with roof product lines. Leading brands offer complete systems including primers, base coats, and topcoats formulated to work together optimally. Their technical support helps contractors and building owners select appropriate products and application methods for specific conditions.

Regional suppliers and distributors play crucial roles in acryldach availability. These companies often stock popular sizes and specifications for immediate pickup, eliminating shipping delays and costs. They provide valuable local knowledge about building codes, climate-appropriate products, and qualified installers.

When selecting suppliers, buyers should consider product availability, technical support quality, warranty terms, and pricing. Requesting product samples allows visual and physical evaluation before committing to large purchases. Verifying UV stabilization specifications ensures long-term performance rather than premature yellowing or degradation.

Building Codes, Standards & Warranties

Understanding regulatory requirements and warranty coverage protects buyers and ensures compliant installations.

Building codes govern many aspects of acryldach installations. International Building Code (IBC) and local amendments specify requirements for load-bearing capacity, fire ratings, glazing safety, and weather resistance. Products must meet or exceed these requirements for legal installation. Manufacturers provide test reports and compliance documentation for their products.

Glazing safety codes require specific materials or protective measures for overhead applications. Impact-resistant acryldach typically satisfies these requirements better than ordinary glass, though testing and certification must confirm compliance. Tempered or laminated products may be required for certain applications.

Fire codes establish requirements based on occupancy type and building construction. Acryldach products are available with various fire ratings from Class A (most restrictive) to Class C. Applications in high-risk occupancies or near property lines may require enhanced fire performance. Local fire marshals can clarify specific requirements.

Wind load requirements vary dramatically by location, with coastal hurricane zones and high-elevation areas demanding greater structural capacity. Acryldach systems must be engineered to resist specified wind pressures without failure. Manufacturers provide load tables showing safe spans and fastening requirements for different wind conditions.

Snow load capacity matters in cold climates where accumulation can create substantial weight. Proper structural design accounts for both dead loads from the roofing system itself and live loads from snow, ice, and maintenance traffic. Conservative design prevents collapse or dangerous deflection.

Industry standards from organizations like ASTM International establish testing methods and performance criteria for acrylic materials. ASTM D4802 covers acrylic sheet properties, while various coating standards address liquid-applied products. Specifying products meeting relevant ASTM standards ensures baseline quality and performance.

Warranties vary considerably among manufacturers and products. Material warranties typically cover defects in manufacturing like delamination, excessive yellowing, or breakage under normal conditions. Coverage periods range from 5-20 years depending on product quality, with premium acrylite sheet products often carrying 10-20 year warranties against excessive yellowing.

Installation warranties from professional contractors cover workmanship issues like leaks from improper sealing or fastener problems. These typically run 1-5 years, with longer periods indicating contractor confidence. Some manufacturers require certified installer programs for extended warranties, ensuring that installation quality doesn’t compromise material performance.

Understanding warranty limitations prevents misunderstandings. Most warranties exclude damage from improper maintenance, chemical exposure, abuse, or natural disasters. They may require regular professional inspections or specific maintenance procedures. Reading warranty terms carefully before purchase clarifies coverage and obligations.

Registering products and installations with manufacturers activates warranties and creates records for future reference. Keeping receipts, installation documentation, and maintenance records supports warranty claims if issues develop. Taking photographs during and after installation provides visual documentation of original condition.

Case Studies & Real-World Examples

Examining actual acryldach installations illustrates the material’s versatility and benefits across different applications.

Residential Projects Using Acryldach

A suburban home in the Pacific Northwest replaced their dark, enclosed patio with a bright, welcoming space using corrugated acryldach panels. The homeowners selected bronze-tinted panels that reduce glare while maintaining 60% light transmission. The installation transformed their outdoor area into a comfortable extension of their living space usable during the region’s frequent rain. Energy monitoring showed a 40% reduction in daytime lighting costs for adjacent interior rooms due to increased natural light penetration. The project cost approximately $6,500 for 35 square meters including professional installation, and the homeowners report complete satisfaction three years later with no maintenance beyond annual cleaning.

Another residential success involved retrofitting skylights in a 1980s ranch home. The original glass skylights had developed leaks and the seals had failed, causing condensation problems. Replacing them with multiwall acryldach panels eliminated the leaks while providing better insulation than the original single-pane glass. The homeowners noticed reduced heating costs during winter and less solar heat gain during summer. The improved thermal performance paid back the $3,200 installation cost through energy savings in approximately five years.

A coastal property installed acryldach panels for a pool enclosure, creating a weatherproof space that extends the swimming season. The clear panels provide unobstructed views while protecting swimmers from wind and rain. The material’s impact resistance has proven valuable, withstanding several severe storms without damage. After four years, the panels maintain their clarity with only routine cleaning, vindicating the owner’s decision to choose acryldach over glass or polycarbonate alternatives.

Commercial & Industrial Applications

A warehouse distribution center in Arizona implemented a daylighting strategy using acryldach skylight panels across 20,000 square meters of roof area. The installation reduced daytime lighting energy consumption by 65%, saving approximately $45,000 annually in electricity costs. The improved lighting quality also reduced worker errors and improved productivity, according to facility managers. The $380,000 investment achieved payback in under nine years, with remaining service life exceeding 15 years, providing ongoing savings.

A shopping mall renovated its aging flat roofs using white acrylic coating systems, transforming what had been a maintenance problem into an asset. The previous built-up roof had developed numerous leaks and required constant patching. The coating restoration extended roof life by an estimated 12-15 years while reducing the building’s cooling costs by approximately $28,000 annually. The $180,000 coating project cost less than one-third what complete roof replacement would have required, making it an easy financial decision.

An agricultural equipment dealership created an attractive covered display area using acryldach panels supported on steel framing. The transparent roof keeps expensive machinery protected from weather while allowing customers to view equipment in natural light. The installation enhanced the property’s curb appeal and created valuable covered space for approximately $18,000, far less than constructing a traditional building addition.

Conclusion

Acryldach represents a remarkable evolution in roofing technology, combining the clarity and beauty of glass with the practicality and durability of advanced polymers. Whether in the form of transparent acrylite sheet panels that flood spaces with natural light or reflective liquid coatings that protect and cool existing roofs, acryldach solutions address real-world challenges while delivering measurable economic and environmental benefits.

The material’s versatility enables applications ranging from residential skylights and patio covers to commercial daylighting systems and agricultural greenhouses. Its superior impact resistance, excellent weather durability, and outstanding light transmission make it preferable to glass for many applications, while its clarity and longevity advantages over polycarbonate and fiberglass justify its selection where optical quality matters most.

Economic considerations favor acryldach when total lifetime costs are evaluated. Initial investments are recovered through reduced energy consumption, lower maintenance expenses, and extended service life compared to alternatives. The substantial energy savings from daylighting and reflective coatings benefit both building owners and the environment by reducing fossil fuel consumption and greenhouse gas emissions.

Proper product selection, professional installation, and routine maintenance ensure that acryldach delivers its full potential. Working with reputable manufacturers, experienced installers, and following established best practices produces reliable, long-lasting results. Understanding building codes, warranty terms, and maintenance requirements helps property owners protect their investments.

As construction practices continue evolving toward sustainability and energy efficiency, acryldach technology positions itself as an increasingly relevant solution. Its ability to reduce lighting and cooling costs while creating pleasant, naturally illuminated spaces aligns perfectly with green building goals. Future innovations in acrylic formulations, coatings, and manufacturing processes promise even better performance and value.

For property owners considering roofing options, acryldach deserves serious evaluation. Its proven track record across diverse applications, strong economic benefits, and positive environmental attributes make it a smart choice for new construction and renovation projects alike. Whether the goal is creating a bright conservatory, protecting a facility with cool roof technology, or simply upgrading aging skylights, acryldach offers solutions worthy of consideration.

Frequently Asked Questions

Is Acryldach better than polycarbonate?

Acryldach offers superior optical clarity and better resistance to yellowing compared to polycarbonate, making it the preferred choice when appearance and light quality are priorities. Polycarbonate provides greater impact resistance, making it better for applications where extreme impacts are likely. For most residential and commercial applications, acryldach’s clarity advantage and scratch resistance make it the better long-term choice, particularly when UV-stabilized products are selected.

Can you walk on an Acryldach roof?

Walking on acryldach panels should be avoided when possible to prevent scratching or damage. If access is necessary for maintenance, using crawl boards or platforms distributes weight and protects surfaces. Multiwall panels are particularly vulnerable to damage from point loads. Liquid acrylic coatings on structural roofs generally support foot traffic for maintenance purposes, though excessive or careless walking can damage the coating and should be minimized.

How to repair leaks in Acryldach panels?

Leak repairs begin with identifying the source, which may not be where water appears inside. Inspect sealant joints, fastener penetrations, and panel edges for gaps or deterioration. Remove failed sealant completely, clean surfaces thoroughly, and apply fresh sealant compatible with acrylic materials. Tighten loose fasteners carefully without overtightening. Replace damaged washers or gaskets. For panel cracks, use acrylic cement for small repairs or replace severely damaged panels. Professional assessment helps for persistent or complex leaks.

For more information, visit Digi Magazine.