Executive Summary

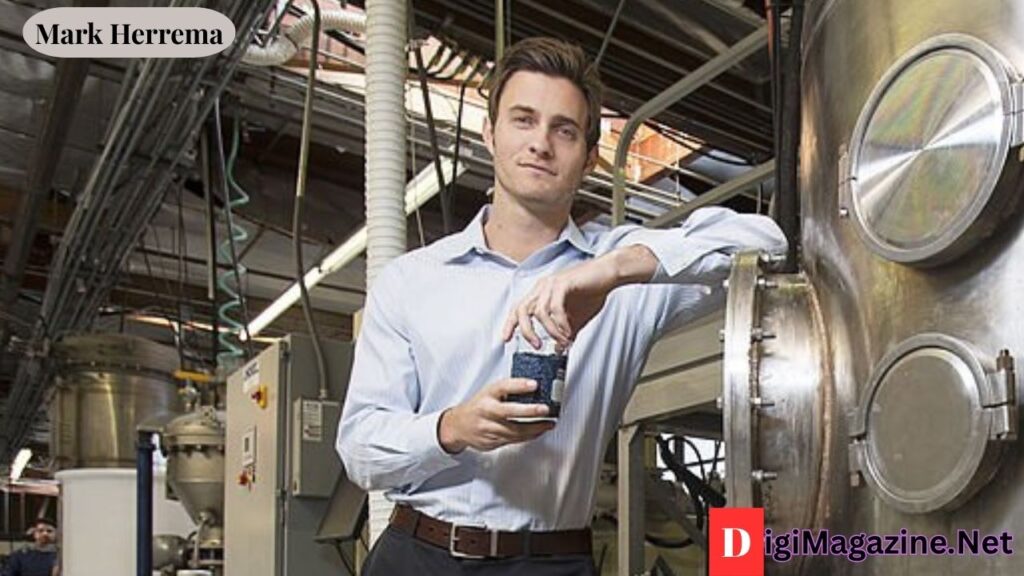

In the rapidly evolving world of climate technology, few entrepreneurs have made as significant an impact as Mark Herrema. As the Co-Founder and Chief Executive Officer of Newlight Technologies, LLC, he has dedicated his career to transforming one of humanity’s most significant challenges into an innovative solution. His vision centers on converting greenhouse gases into valuable materials, fundamentally reimagining how industries approach carbon emissions.

Newlight Technologies, LLC stands at the forefront of the circular economy movement, developing breakthrough processes that capture carbon from the air and ocean and transform it into high-performance materials. Under his leadership, the company has pioneered AirCarbon technology—a revolutionary material that is not just carbon-neutral, but actually carbon-negative. This means that every product made removes more greenhouse gases from the atmosphere than it emits during production.

The achievements under his guidance have garnered international recognition, positioning the company as a leader in sustainable materials innovation. From partnerships with major global brands to recognition from environmental organizations, the impact of his work extends far beyond the walls of his California-based company.

Background and Early Career

The journey of Mark Herrema into the world of environmental innovation began with a deep-rooted passion for solving complex problems. His educational foundation provided him with the analytical skills and scientific understanding necessary to tackle one of the world’s most pressing issues: climate change.

During his early professional experiences, he developed a keen awareness of the disconnect between industrial production and environmental sustainability. Traditional manufacturing processes relied heavily on fossil fuels and generated significant carbon emissions. This realization sparked a question that would define his career: What if greenhouse gases could be transformed from a liability into an asset?

His path to entrepreneurship wasn’t straightforward. Like many visionary founders, he spent years researching, experimenting, and refining his ideas before leaping. The entrepreneurial journey required not just technical expertise but also unwavering determination and the ability to see possibilities where others saw only problems.

The vision that led to the founding of his company emerged from a simple yet profound insight: nature already has a mechanism for converting carbon dioxide into functional materials through photosynthesis. The challenge was to replicate and accelerate this process in a way that could scale industrially and compete economically with traditional materials.

Founding of Newlight Technologies

Newlight Technologies, LLC was established in 2003, born from a partnership that combined scientific innovation with business acumen. Mark Herrema, alongside his co-founder Kenton Kimmel, embarked on a mission that many considered impossible: to create a profitable business model around carbon capture and utilization.

The initial inspiration came from observing natural carbon cycles. Plants capture carbon dioxide and, through photosynthesis, convert it into organic matter. The founders asked themselves: Could a similar process be engineered at an industrial scale to create commercially viable materials? This question became the foundation of their research and development efforts.

Early challenges were substantial. Convincing investors to fund an unproven technology required persistence and compelling evidence. The scientific community was skeptical about whether carbon-based materials could compete with established plastics and materials. Additionally, developing the technology needed years of research, countless experiments, and significant financial investment before yielding tangible results.

The breakthrough moment came when the team successfully demonstrated that they could capture greenhouse gases and convert them into a thermoplastic material with properties comparable to petroleum-based plastics. This wasn’t just a laboratory curiosity—it was a commercially viable product that could replace conventional materials across multiple industries.

The company’s mission crystallized around a core principle: to transform the way the world views carbon. Rather than treating greenhouse gases as waste products to be minimized or offset, Newlight Technologies, LLC would make them valuable raw materials. This shift in perspective represented a fundamental reimagining of industrial processes.

Core values at the company emphasize innovation, transparency, and environmental responsibility. The leadership established a culture where scientific rigor meets entrepreneurial drive, where failure is viewed as a learning opportunity, and where the ultimate goal is measurable environmental impact.

Newlight’s Revolutionary Technology

The cornerstone of the company’s innovation is AirCarbon technology—a process that fundamentally changes how materials can be manufactured. At its core, AirCarbon represents a biocatalytic conversion process that mimics and accelerates natural carbon cycles.

The carbon capture and utilization process begins with sourcing greenhouse gases from various industrial sources, including methane from farms and carbon dioxide from industrial facilities. These gases, which would otherwise be released into the atmosphere, become the primary raw material for production.

Converting greenhouse gases into materials involves a sophisticated multi-step process. First, microorganisms act as biocatalysts, consuming the carbon-based gases. These microorganisms naturally produce a polymer called polyhydroxyalkanoate (PHA) as they metabolize carbon. The PHA is then harvested, purified, and processed into AirCarbon material—a thermoplastic that can be melted, molded, and manufactured into countless products.

The scientific innovation behind this process has been protected through numerous patents, securing the company’s intellectual property and competitive position. These patents cover various aspects of the production process, from the specific microbial strains used to the optimization of conversion efficiency and the final material properties.

Environmental impact and sustainability metrics tell a compelling story. For every kilogram of AirCarbon produced, the process captures and converts approximately 88 kilograms of carbon dioxide equivalent. This means the material is not just carbon-neutral—it actively removes more greenhouse gases from the atmosphere than the entire production process emits. Independent third-party verification, including carbon certification from standards organizations, validates these claims.

The technology represents a paradigm shift in materials science. Traditional plastics rely on extracting petroleum from the ground, refining it through energy-intensive processes, and creating materials that persist in the environment for centuries. AirCarbon, by contrast, uses waste carbon as feedstock, requires less energy to produce, and can biodegrade in marine environments.

Business Development and Growth

The product development timeline at Newlight Technologies, LLC spans more than two decades of continuous innovation. The early years focused on proving the concept and optimizing the biocatalytic process. The 2010s brought commercialization efforts, with the first AirCarbon products reaching the market.

Major milestones include achieving commercial-scale production, securing significant partnerships with global brands, and demonstrating that carbon-negative materials can compete on both performance and price with conventional alternatives. Each milestone represented years of work, overcoming technical challenges, and building market confidence.

Scaling efforts required substantial investment in manufacturing capabilities. The company developed proprietary production facilities designed to maximize conversion efficiency while maintaining the carbon-negative profile of the materials. These facilities represent a new generation of manufacturing—where the factory itself contributes to environmental restoration rather than degradation.

Manufacturing capabilities continue to expand as demand for sustainable materials grows. The production process is designed to be modular and scalable, allowing for increased output without compromising the environmental benefits. This scalability is crucial for the company’s vision of displacing petroleum-based materials on a global scale.

Market positioning emphasizes both environmental performance and material quality. AirCarbon competes directly with traditional plastics, offering comparable or superior properties in durability, moldability, and aesthetic appeal. The competitive advantage lies not just in sustainability but in creating a product that performs exceptionally well in real-world applications.

Key partnerships and collaborations span multiple industries. Fashion brands, furniture manufacturers, automotive companies, and consumer goods producers have all explored or implemented AirCarbon in their products. These partnerships validate the material’s versatility and commercial viability while expanding market reach.

Products and Applications

AirCarbon material properties make it suitable for a wide range of applications. The thermoplastic can be molded into virtually any shape, accepts various finishes and colors, and offers durability comparable to conventional plastics. Its smooth finish and professional appearance make it attractive for consumer-facing products.

Product lines have expanded significantly since the company’s founding. Furniture represents one of the most visible applications, with chairs, tables, and office accessories made entirely from AirCarbon. These pieces demonstrate that sustainable materials can meet high standards for design, comfort, and longevity.

The fashion industry has embraced AirCarbon for accessories, including sunglasses, bags, and fashion elements. Luxury and mainstream brands alike appreciate the material’s aesthetic qualities and the compelling sustainability story it offers consumers. Fashion applications showcase the material’s versatility and appeal across different market segments.

Packaging represents an enormous opportunity for impact. Single-use plastics account for a significant portion of environmental plastic pollution. AirCarbon packaging offers a carbon-negative alternative that performs well for food-safe applications while biodegrading in marine environments if it reaches the ocean.

Commercial partnerships with brands using AirCarbon continue to grow. Each partnership serves as both a revenue stream and a proof point for the technology. Major corporations increasingly seek sustainable material alternatives, driven by consumer demand, regulatory pressure, and corporate sustainability commitments.

Consumer and industrial applications span an impressive range. Beyond furniture and fashion, AirCarbon appears in automotive components, electronics housings, consumer goods, and industrial parts. Each application demonstrates the material’s technical capabilities while contributing to carbon reduction goals.

Leadership Philosophy

The management style and approach of Mark Herrema emphasize collaboration, transparency, and mission-driven decision-making. He leads with the understanding that transforming entire industries requires not just technological innovation but also cultural change within the organization and beyond.

Innovation culture at Newlight Technologies, LLC, thrives on curiosity and experimentation. Team members are encouraged to challenge assumptions, propose novel solutions, and pursue ideas that might seem impractical at first glance. This culture has been essential for achieving breakthroughs that conventional thinking would dismiss as impossible.

Team building and talent development focus on attracting individuals who are motivated by more than just financial compensation. The company seeks individuals passionate about environmental impact, willing to tackle challenging problems, and committed to its long-term vision of transforming global materials production.

The long-term vision for the company extends beyond commercial success. The ultimate goal is to demonstrate that carbon-negative production is not just possible but economically superior to traditional methods. This would trigger a fundamental shift in how industries approach manufacturing, with carbon capture becoming not a cost center but a profit center.

Industry Impact and Recognition

Awards and honors received by Mark Herrema and Newlight Technologies, LLC reflect the significance of their contributions. Recognition has come from environmental organizations, business associations, technology forums, and governmental bodies. These accolades validate the scientific achievements and commercial viability of the technology.

Speaking engagements and thought leadership have positioned him as an influential voice in sustainability and climate technology. He regularly presents at conferences, contributes to industry discussions, and participates in forums shaping the future of materials science and environmental policy.

Media coverage and public profile have grown as awareness of carbon capture technologies increases. Major business publications, environmental media, and technology outlets have profiled the company’s work, highlighting the potential for converting greenhouse gases into commercial products.

Influence on the circular economy movement cannot be overstated. Newlight Technologies, LLC exemplifies the principles of the circular economy: waste from one process becomes the input for another, materials are designed for multiple lifecycles, and environmental restoration is built into the business model itself.

Challenges and Lessons Learned

Technical obstacles overcome include optimizing the biocatalytic process for commercial scale, achieving consistent material properties, and developing manufacturing processes that maintain carbon-negative credentials at high volumes. Each obstacle required innovative solutions and often years of patient experimentation.

Market adoption challenges stemmed from the natural conservatism of industries accustomed to established materials. Convincing manufacturers to try a new material, even one with superior environmental credentials, required extensive testing, performance validation, and economic analysis. Building trust and demonstrating reliability took time and persistence.

Scaling difficulties emerged as the company moved from laboratory to commercial production. Biological processes that work beautifully at a small scale can behave unpredictably when scaled up. Managing microbial cultures, maintaining optimal conditions, and achieving consistent output at industrial volumes required sophisticated process controls and continuous refinement.

Key learnings from the entrepreneurial journey include the importance of persistence, the value of rigorous scientific validation, and the necessity of economic viability. Environmental benefits alone aren’t sufficient—successful climate technologies must also make business sense. This reality has shaped strategic decisions throughout the company’s development.

Future Vision

Expansion plans for Newlight Technologies, LLC include increasing production capacity, entering new markets, and developing additional applications for AirCarbon technology. Geographic expansion could bring production facilities closer to carbon sources and key markets, reducing transportation emissions and improving economics.

The technology development roadmap continues to focus on improving conversion efficiency, expanding the range of materials that can be produced, and exploring new sources of greenhouse gases as feedstock. Each improvement increases the environmental impact and economic competitiveness of the technology.

Industry transformation goals are ambitious. The vision extends beyond replacing some petroleum-based plastics to fundamentally changing how materials are produced across industries. If successful, carbon capture could shift from a climate mitigation strategy to a core element of profitable manufacturing.

Climate change mitigation objectives drive every decision at the company. The potential impact is substantial: if carbon-negative materials displaced even a fraction of conventional plastics and materials, the cumulative greenhouse gas reductions would be measured in millions of tons annually. This scale of impact motivates the team’s continued innovation and growth efforts.

Personal Insights

The motivations and driving forces behind Mark Herrema’s work stem from a belief that human ingenuity can solve even the most daunting challenges. Climate change represents an existential threat, but it also presents an opportunity to reimagine industrial processes in ways that restore rather than degrade the environment.

Work-life balance approaches acknowledge the intensity required to build a transformative company while maintaining perspective and avoiding burnout. The entrepreneurial journey is measured in decades, not quarters, requiring sustainable personal practices that support long-term commitment.

Advice for aspiring entrepreneurs emphasizes the importance of solving real problems, validating assumptions through rigorous testing, and maintaining focus despite inevitable setbacks. The path from concept to commercial success is rarely linear, and resilience becomes as essential as intelligence or technical skill.

Perspective on sustainability and innovation reflects a pragmatic optimism. Technology alone won’t solve climate change, but it can provide the tools necessary for a sustainable future. Success requires not just innovation but also effective business models, supportive policies, and shifts in consumer behavior.

Conclusion

The legacy and ongoing impact of Mark Herrema’s work at Newlight Technologies, LLC will be measured not just in commercial success but in environmental restoration. By demonstrating that carbon-negative materials can compete in the marketplace, he has opened a pathway for industries to contribute positively to climate solutions.

Contribution to the climate technology sector includes both the specific innovations of AirCarbon and the broader demonstration that greenhouse gases can be valuable resources. This reframing of the problem has inspired other entrepreneurs and researchers to explore carbon utilization approaches across different applications and industries.

The future outlook for Newlight Technologies, LLC appears promising as awareness of climate change intensifies and demand for sustainable materials grows. The company is well-positioned to capitalize on these trends while staying true to its mission of environmental restoration through innovative materials science.

As industries worldwide strive to reduce their carbon footprints, the model pioneered by Mark Herrema and Newlight Technologies, LLC presents a compelling path forward—one where environmental responsibility and commercial success are not competing priorities but complementary objectives.

For more information, visit Digi Magazine.