Introduction to Repmold Technology

In the world of modern manufacturing, precision and efficiency stand as pillars of success. Repmold represents a specialized category of molds designed specifically for injection molding processes that deliver exceptional results across multiple industries. From automotive components to medical devices, this technology has transformed how manufacturers approach production challenges.

The injection molding industry continues to evolve, and Repmold solutions have emerged as a preferred choice for companies seeking high-quality output combined with cost-effectiveness. Understanding this technology helps manufacturers make informed decisions about their production processes and equipment investments.

What is Repmold?

Repmold refers to a specific type of mold used in the process of injection molding, a manufacturing technique commonly employed in industries such as automotive, electronics, medical devices, and consumer goods. The term Repmold is often associated with high-quality, precise, and efficient molding solutions. These molds are designed to produce plastic or metal components with high accuracy and in large volumes.

This technology plays a critical role in ensuring the creation of parts that meet both aesthetic and functional requirements while maintaining cost-effectiveness. The design principles behind these molds focus on durability, repeatability, and precision to achieve consistent results across production runs.

The Manufacturing Process Behind Repmold

The manufacturing process for Repmold involves several carefully orchestrated stages that ensure optimal results. Understanding this process helps manufacturers appreciate the complexity and sophistication of modern molding technology.

Design and Engineering Phase

The journey begins with detailed design work using computer-aided design software. Engineers create precise specifications that account for material flow, cooling channels, and part geometry. This phase determines the success of the final product and requires expertise in both design principles and material science.

Mold Construction

Once designs are finalized, skilled craftsmen and automated machinery work together to construct the physical mold. This stage involves precision machining, heat treatment, and surface finishing to create cavities that will shape the final components. The quality of construction directly impacts the longevity and performance of the mold.

Material Selection and Preparation

Choosing the right materials for both the mold and the parts it produces is crucial. Different applications require different material properties, from high-temperature resistance to chemical stability. The preparation phase ensures materials meet specifications before production begins.

Injection Molding Cycle

The actual production cycle involves heating material until it reaches a molten state, injecting it into the mold cavity under high pressure, allowing it to cool and solidify, and then ejecting the finished part. This cycle repeats thousands or even millions of times throughout the mold’s lifetime.

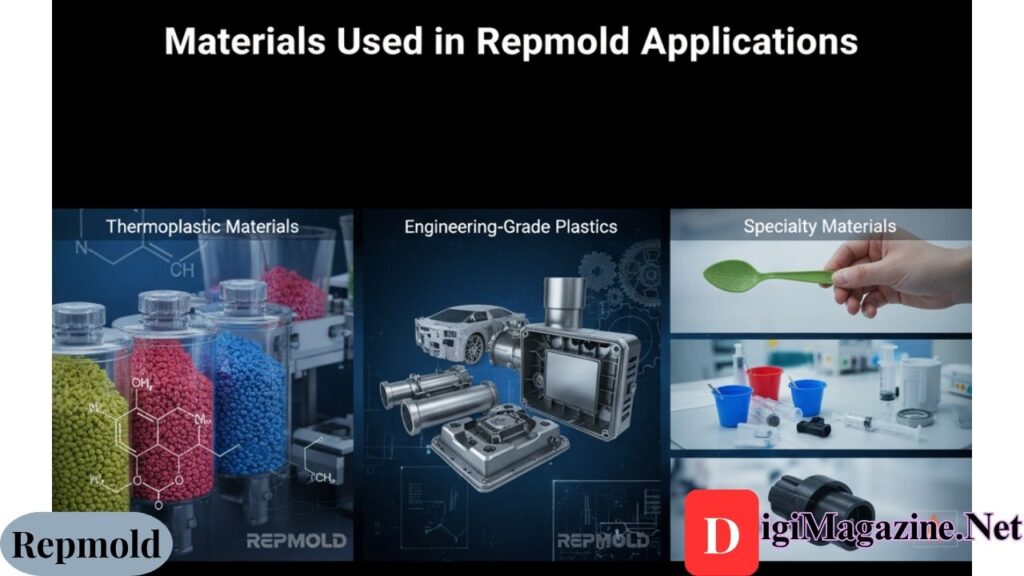

Materials Used in Repmold Applications

The versatility of this technology stems partly from the wide range of materials it can process. Each material brings unique properties that suit specific applications and requirements.

Thermoplastic Materials

Thermoplastics represent the most common material category for injection molding processes. These materials can be heated, molded, and reheated multiple times without significant degradation. Popular options include polypropylene, polyethylene, and polystyrene, each offering distinct characteristics for different applications.

Engineering-Grade Plastics

For applications requiring superior mechanical properties, engineering-grade plastics provide enhanced strength, temperature resistance, and dimensional stability. Materials like nylon, polycarbonate, and ABS fall into this category and are commonly used in automotive and industrial applications.

Specialty Materials

Certain applications demand specialized materials with unique properties. These might include biodegradable plastics for environmental considerations, medical-grade materials for healthcare applications, or flame-retardant compounds for safety-critical components.

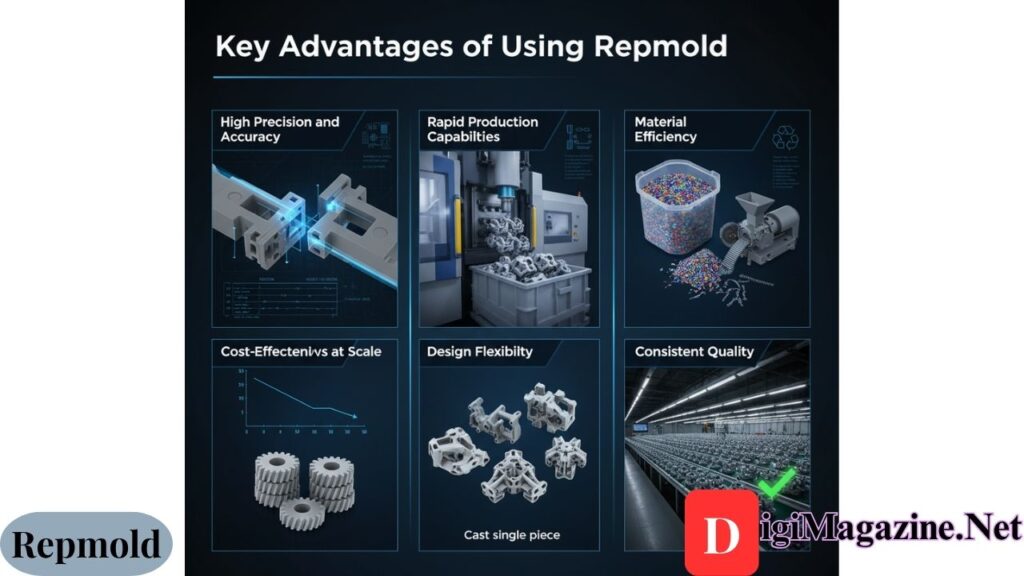

Key Advantages of Using Repmold

The adoption of this molding technology brings numerous benefits that explain its widespread popularity across industries.

High Precision and Accuracy

One of the most significant advantages lies in the ability to produce components with tight tolerances and consistent dimensions. This precision ensures parts fit together correctly in assemblies and perform their intended functions reliably.

Cost-Effectiveness at Scale

While initial tooling costs may seem substantial, the per-unit cost decreases dramatically as production volumes increase. This makes the technology highly economical for medium to large production runs.

Rapid Production Capabilities

Modern injection molding systems can complete cycles in seconds, enabling the production of thousands of parts per day. This speed allows manufacturers to meet demanding schedules and respond quickly to market demands.

Design Flexibility

The technology accommodates complex geometries, intricate details, and multiple features in a single part. This flexibility reduces the need for secondary operations and assembly steps, further improving efficiency.

Material Efficiency

The process generates minimal waste compared to other manufacturing methods. Excess material can often be recycled and reused, contributing to sustainable manufacturing practices.

Consistent Quality

Once properly set up, the process delivers remarkably consistent results across production runs. This reliability reduces defect rates and ensures customer satisfaction.

Industry Applications and Use Cases

The versatility of Repmold technology has led to its adoption across numerous sectors, each leveraging its unique advantages.

Automotive Industry

The automotive sector relies heavily on injection molding for producing interior components, exterior trim pieces, under-hood parts, and structural elements. The technology’s ability to create lightweight yet durable parts contributes to vehicle efficiency and performance.

Medical Devices and Healthcare

Medical device manufacturers value the precision and cleanliness achievable with modern molding processes. From surgical instruments to diagnostic equipment housings, the technology meets stringent regulatory requirements while maintaining cost-effectiveness.

Electronics Industry

Consumer electronics depend on precisely molded casings, connectors, and internal components. The technology’s ability to incorporate features like snap fits, threads, and mounting points reduces assembly complexity.

Consumer Goods

Everyday products from kitchen utensils to toys utilize injection molding extensively. The process enables mass production of affordable, durable items that meet consumer expectations for quality and functionality.

Industrial Equipment

Components for machinery, tools, and industrial systems benefit from the strength and precision that modern molding technology provides. These applications often require materials that withstand harsh environments and demanding conditions.

Technical Considerations and Best Practices

Achieving optimal results with injection molding requires attention to numerous technical factors throughout the process.

Wall Thickness Optimization

Maintaining uniform wall thickness throughout a part helps ensure even cooling and reduces the risk of defects like warping or sink marks. Designers must balance structural requirements with processing considerations.

Draft Angles and Ejection

Incorporating appropriate draft angles facilitates easy part removal from the mold cavity. This seemingly small detail significantly impacts production efficiency and part quality.

Gate Location and Design

Where and how material enters the mold cavity affects flow patterns, weld lines, and surface finish. Strategic gate placement optimizes these factors for the best possible results.

Cooling System Design

Efficient cooling reduces cycle times and improves part quality. Well-designed cooling channels maintain consistent temperatures throughout the mold, preventing hot spots and ensuring uniform cooling.

Challenges and Considerations

Despite its many advantages, the technology presents certain challenges that manufacturers must address.

Initial Investment Requirements

The upfront cost of designing and manufacturing molds can be substantial, particularly for complex parts. This investment must be justified by production volumes and long-term benefits.

Lead Time for Tool Development

Creating high-quality molds takes time, from initial design through final testing and refinement. Manufacturers must plan accordingly to meet project timelines.

Design Limitations

While the technology offers great flexibility, certain geometric features may be difficult or impossible to mold. Designers must understand these limitations and work within them.

Material Selection Complexity

Choosing the right material requires balancing multiple factors, including mechanical properties, processing characteristics, cost, and environmental considerations. This decision significantly impacts final product performance.

Quality Control and Testing

Maintaining consistent quality requires robust testing and inspection procedures throughout the production process.

Dimensional Inspection

Regular measurement of critical dimensions ensures parts remain within specified tolerances. Modern measuring equipment enables rapid, accurate verification of part geometry.

Visual Inspection

Trained inspectors examine parts for surface defects, color consistency, and overall appearance. Automated vision systems increasingly supplement human inspection for improved consistency.

Mechanical Testing

Depending on the application, parts may undergo strength testing, impact testing, or other mechanical evaluations to verify they meet performance requirements.

Process Monitoring

Advanced monitoring systems track process parameters in real-time, alerting operators to deviations that could affect quality. This proactive approach prevents defects before they occur.

Future Trends and Innovations

The injection molding industry continues to evolve, with new technologies and approaches emerging regularly.

Automation and Industry 4.0

Smart manufacturing technologies integrate sensors, data analytics, and automated control systems to optimize production processes. These systems enable predictive maintenance, quality prediction, and improved efficiency.

Sustainable Manufacturing

Environmental concerns drive innovation in materials and processes. Biodegradable plastics, recycled materials, and energy-efficient equipment represent growing trends in the industry.

Advanced Materials Development

Researchers continuously develop new materials with enhanced properties, expanding the range of possible applications for injection molding technology.

Additive Manufacturing Integration

Combining traditional molding with 3D printing technologies opens new possibilities for rapid prototyping, custom tooling, and hybrid manufacturing approaches.

Selecting the Right Partner for Your Project

Success with injection molding often depends on choosing the right manufacturing partner who understands your requirements and possesses the necessary expertise.

Technical Expertise

Look for partners with demonstrated experience in your industry and with similar parts. Their technical knowledge helps avoid common pitfalls and optimize designs for manufacturability.

Quality Systems

Reputable manufacturers maintain comprehensive quality management systems, often certified to international standards. These systems ensure consistent quality and traceability throughout production.

Communication and Collaboration

An effective partnership requires clear communication and collaborative problem-solving. Choose partners who engage proactively and keep you informed throughout the project.

Capacity and Scalability

Ensure your chosen partner can handle your current production needs while accommodating future growth. Production capacity, equipment capabilities, and financial stability all factor into this assessment.

Conclusion

Repmold technology represents a cornerstone of modern manufacturing, enabling the efficient production of high-quality components across diverse industries. Its combination of precision, speed, and cost-effectiveness makes it an attractive option for companies seeking to optimize their manufacturing processes.

Understanding the technology, from material selection through quality control, empowers manufacturers to make informed decisions about their production strategies. While challenges exist, the benefits typically far outweigh the drawbacks for appropriate applications.

As the industry continues to evolve with new materials, technologies, and approaches, injection molding will likely remain a vital manufacturing method for years to come. Whether you’re producing automotive parts, medical devices, consumer goods, or industrial components, this technology offers solutions that meet demanding requirements while maintaining economic viability.

For manufacturers considering this technology for their projects, investing time in understanding the process, selecting appropriate materials, and partnering with experienced providers pays dividends in product quality, production efficiency, and long-term success.

For more information, visit Digi Magazine.